Preparation of zinc coating samples used for metallographic analysis of the challenge

Because of the hardness and thickness of the zinc coating will have differences, so in the process of metallographic sample preparation have different performance.In addition, some of the zinc coating will react with water and makes the sample preparation process difficult.

With the sampleThe challenges in the process of

Galvanized samples with sample can be a challenge, especially in the case of pressed for time.In order to avoid shrinkage clearance, must ensure that the correct adhesion between materials and samples.

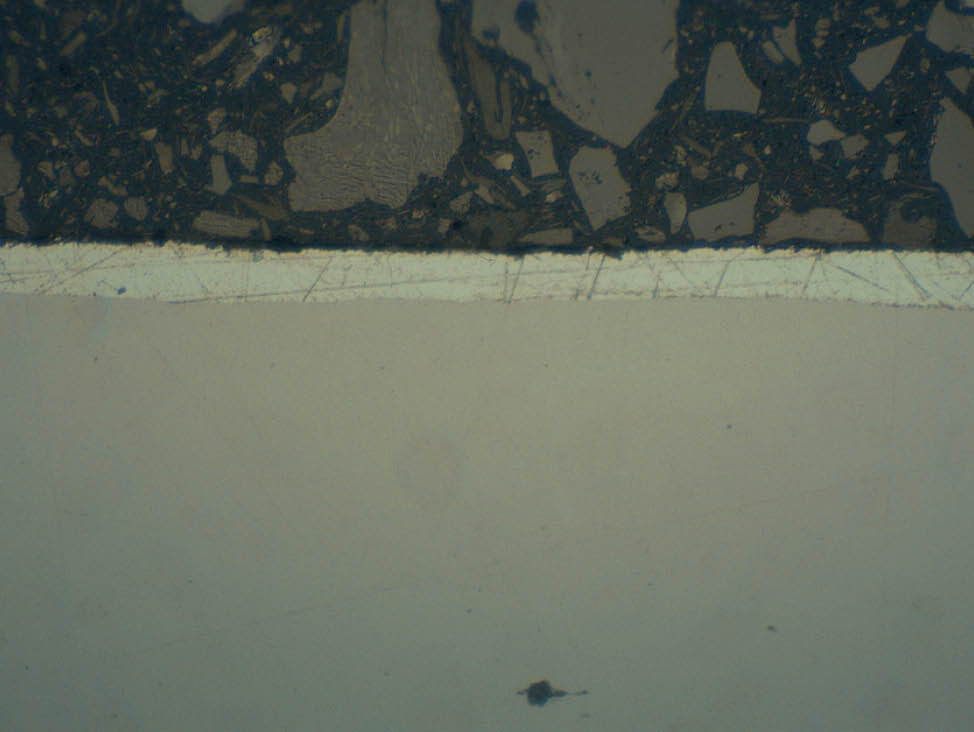

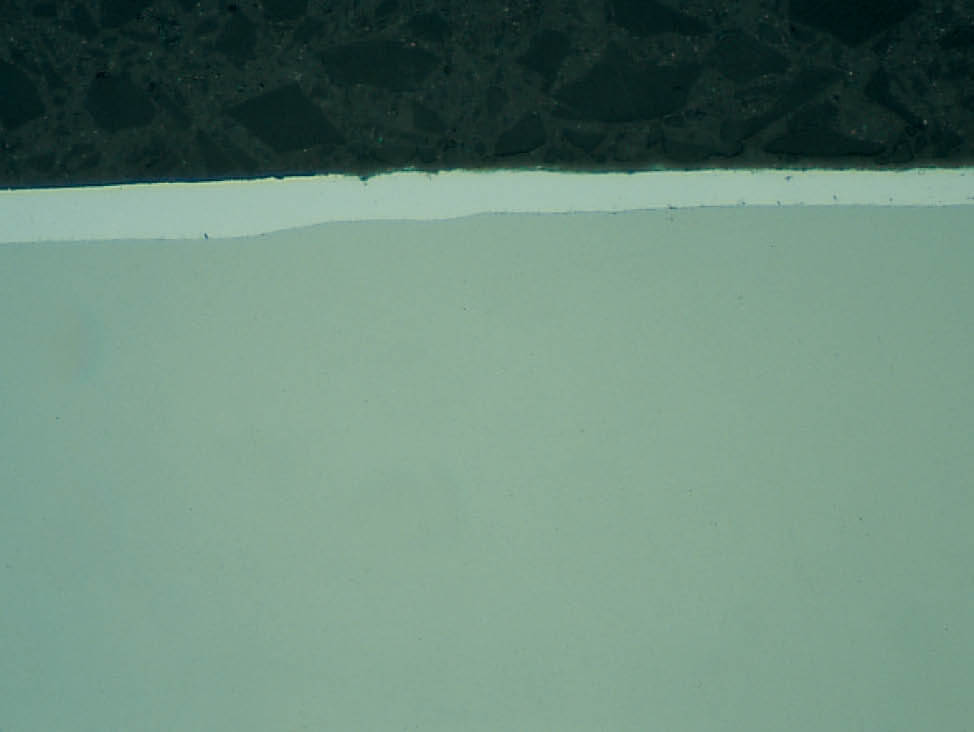

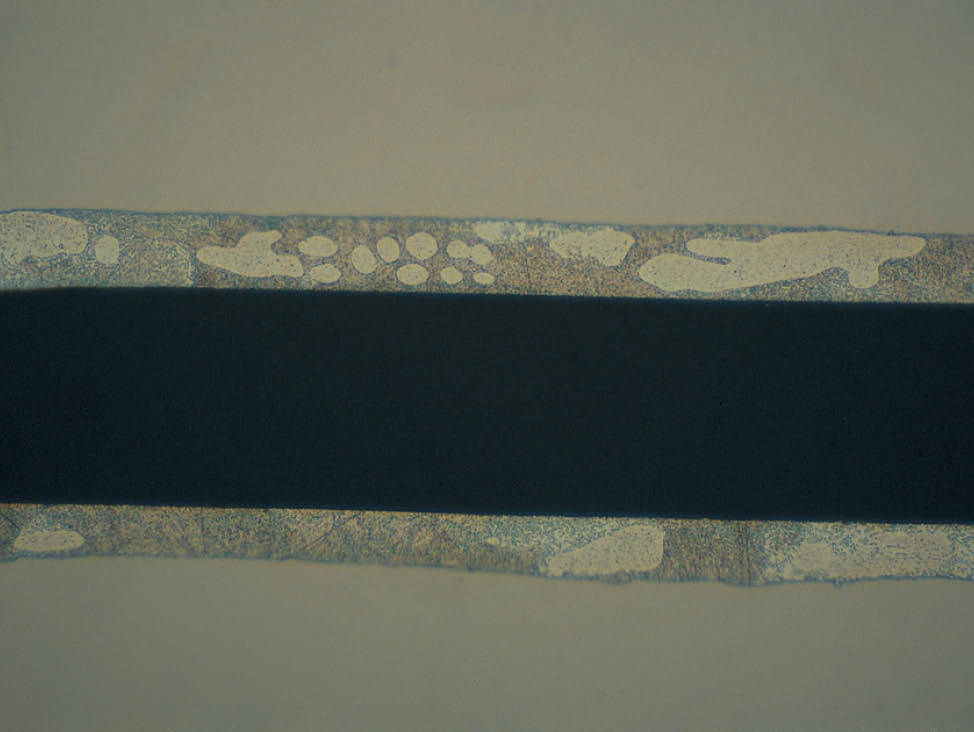

Figure 6: between sample and resin shrinkage clearance can cause water damage and alcohol stains, as well as the round corner and grinding debris residues, 200 x

Grinding andpolishingThe challenge of steps

According to the purity of zinc coating, zinc coating will become more soft and more sensitive to water, especially ordinary hot dip plating and electrolytic deposition coating, zinc content is very high.This will make them soft and prone to mechanical deformation.They do not clean with water.

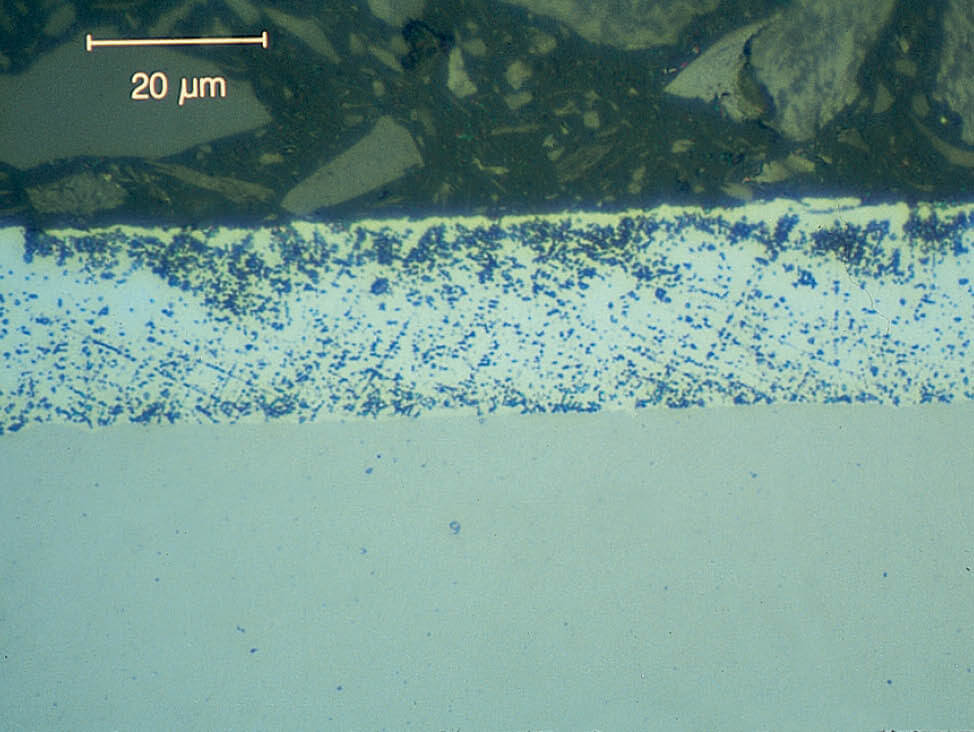

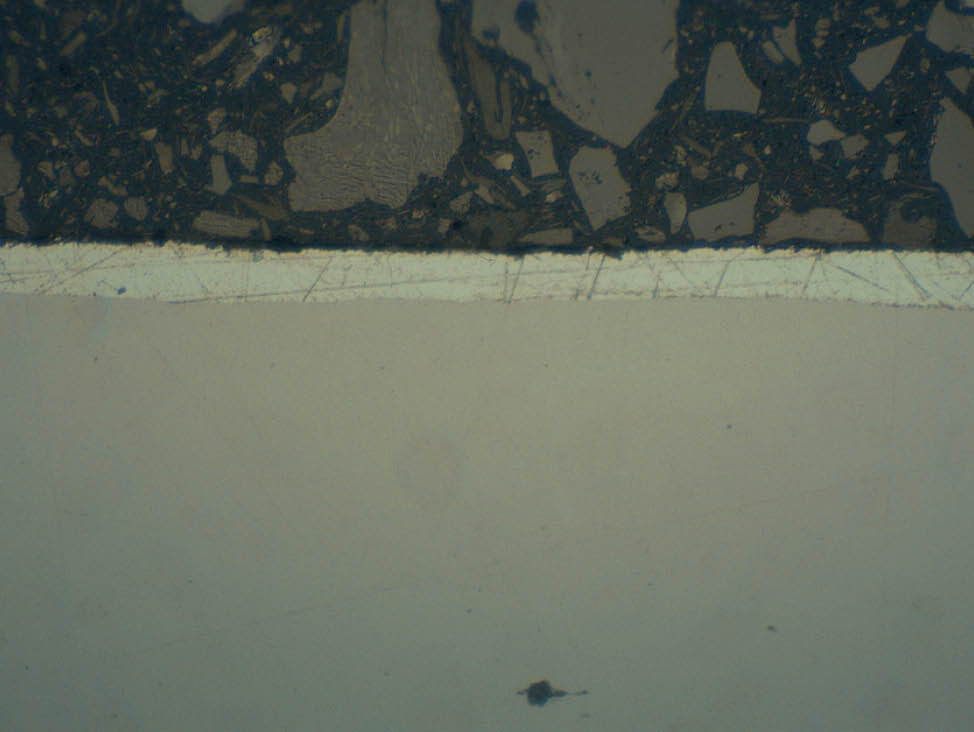

Figure 7: soft coating, grinding and polishing scratches, can be seen 500 x

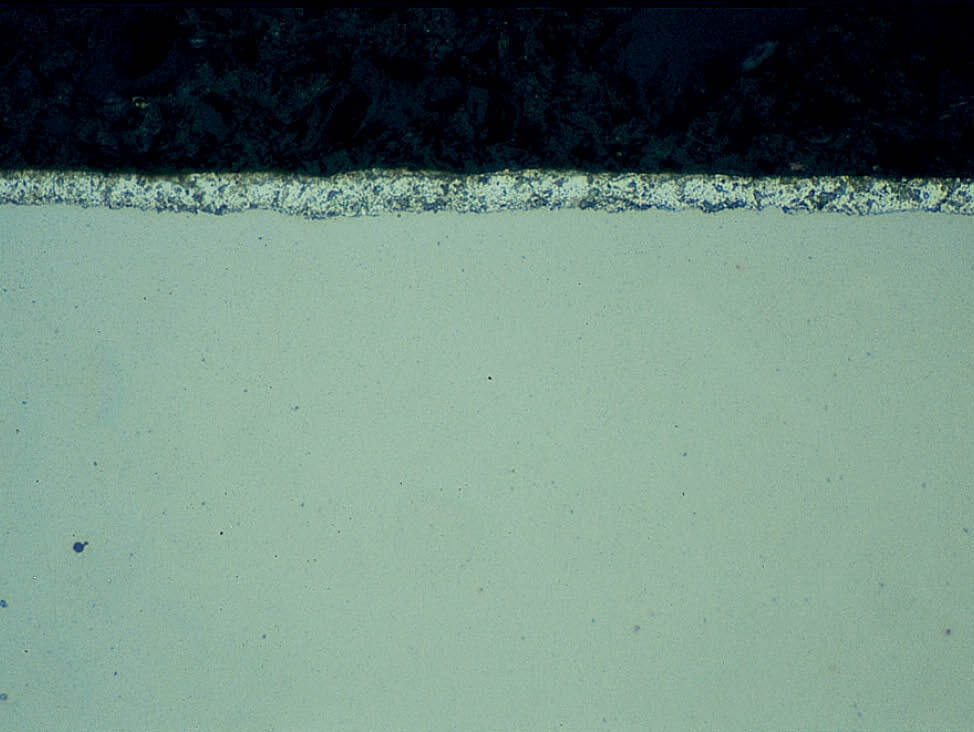

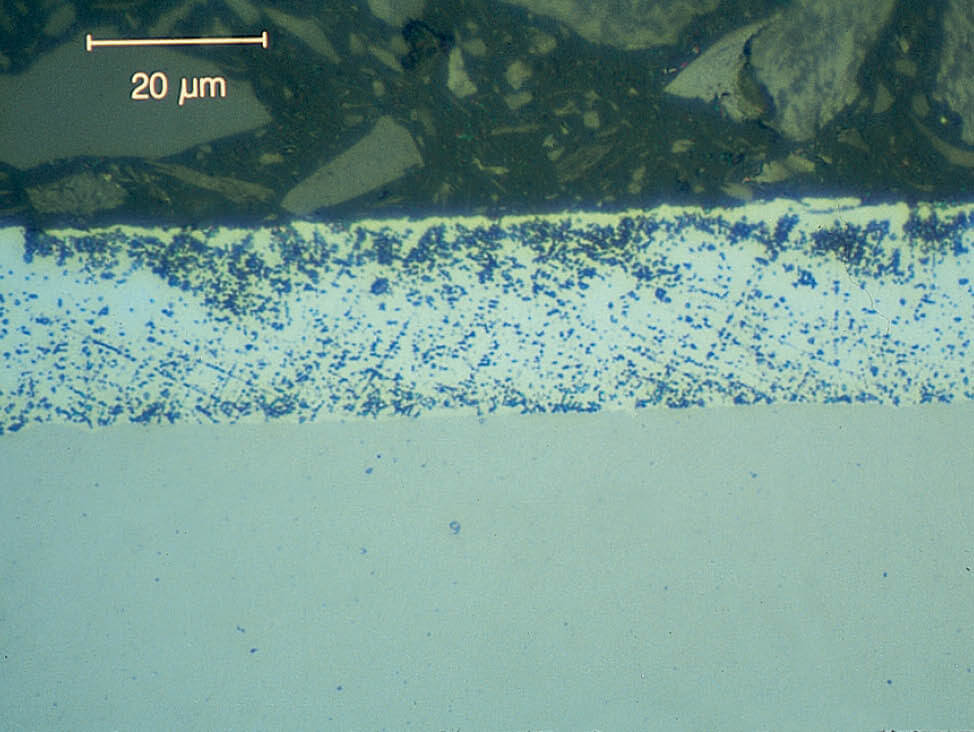

Figure 8: zinc and lead to change color after reaction with water erosion, 1000 x