The production of powder metallurgy parts

A lot of different metal can be used in the production of powder metallurgy parts, including iron, copper and steel powder.

The production process of iron and steel powder

Powder production

Powder production

There are two kinds of powder production methods: chemical method and spray method.

- Chemical method: under the temperature below the melting point of metal oxides directly from the ore into metal powder.

- Through the nozzle atomization method: molten metal alloy, and the high pressure water or gas jet impact.Of granular form droplets, and curing.

The generation, mixed metal powder.At this stage, you can add other elements, including lubricants, carbon and/or alloying elements.

In cemented carbide die medium pressure tight powder

In order to production parts, mixed powder under high pressure in cemented carbide die medium pressure tight.At this stage, the parts have the shape of the final product, but do not have the strength of the requirements.These parts is known as the "green" parts.

Sintering parts

In order to provide the necessary mechanical and physical properties, in the protective gas in high temperature sintering process was carried out on the parts.Through cooperation with diffusion between adjacent grain produce key.

The final processing

According to the application, some parts may be additional processing, including hot isostatic pressing, immersion, the surface hardening or plating.

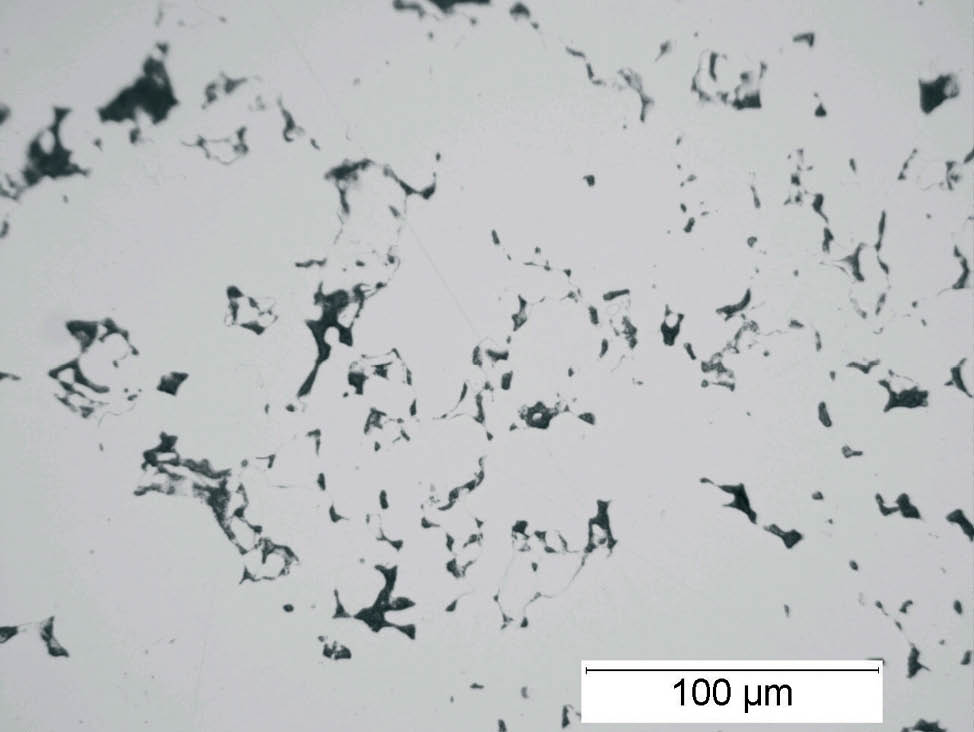

Figure 4: sponge iron powder, SEM

Figure 4: sponge iron powder, SEM