Fastener production and technology of fasteners

Simple unthreaded metal fasteners (such as pin and connecting rod) is one of the most ancient of fastening technology.Threaded rivets, screws and bolts are succeeding, the original is made of precious metals production.

Fastener technology development is one of the biggest can run under pressure the ductility of the metal.At this point, the use of cold forming of metal fasteners for mass production.Today, the widespread adoption of no cutting forming (rolling), by cold or hot press molding.

Cold forming of metal fasteners

Cold is the most commonly used method so far in the production of metal fasteners.Be incorporated into continuous wire extrusion machine.Then, use the mold compression wire and reducing its diameter, until to form the correct shape.Threaded through cold rolling forming.In some cases, the induction hardening can be used to increase the surface hardness of metal fasteners.

- In order to obtain high quality steel fasteners, can adopt different methods of heat treatment to obtain specific material properties.

- Low carbon steel after carburizing treatment, can form hard surface and the center of the flexible structure.

- Carbon steel after quenching and tempering treatment.

- High quality of screws can be processed after the initial forming structure, to achieve a specific shape, tolerance, and surface.

Hot forming of metal fasteners

Thermoforming can still be used for very large or complex shape metal bolt.

Metal fasteners, anti-corrosion protection

In order to improve the anti-corrosion performance, can be coated on fasteners manganese phosphate, zinc phosphate, or iron phosphate, and then coated with grease.If you need more strong anticorrosion performance, can be in metal fasteners, zinc and cadmium and chromium, or by cadmium and aluminum vapor deposition.

To learn more

Understanding the production of various metal fasteners, process and technical details,

Please download the complete application instructions.

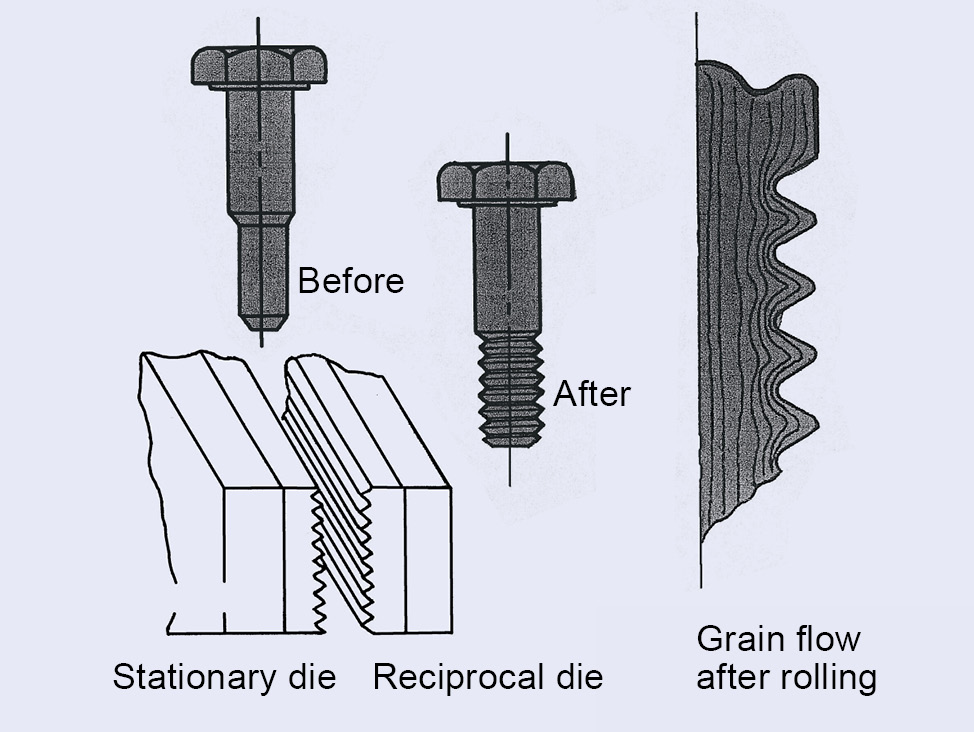

Figure 3: cold heading is a kind of basic processing methods, can be in the "cold" state will round wire into the shape of the necessary.Must maintain the continuity of grain processing, in order to ensure the integrity of the metal fasteners.

Figure 3: cold heading is a kind of basic processing methods, can be in the "cold" state will round wire into the shape of the necessary.Must maintain the continuity of grain processing, in order to ensure the integrity of the metal fasteners.

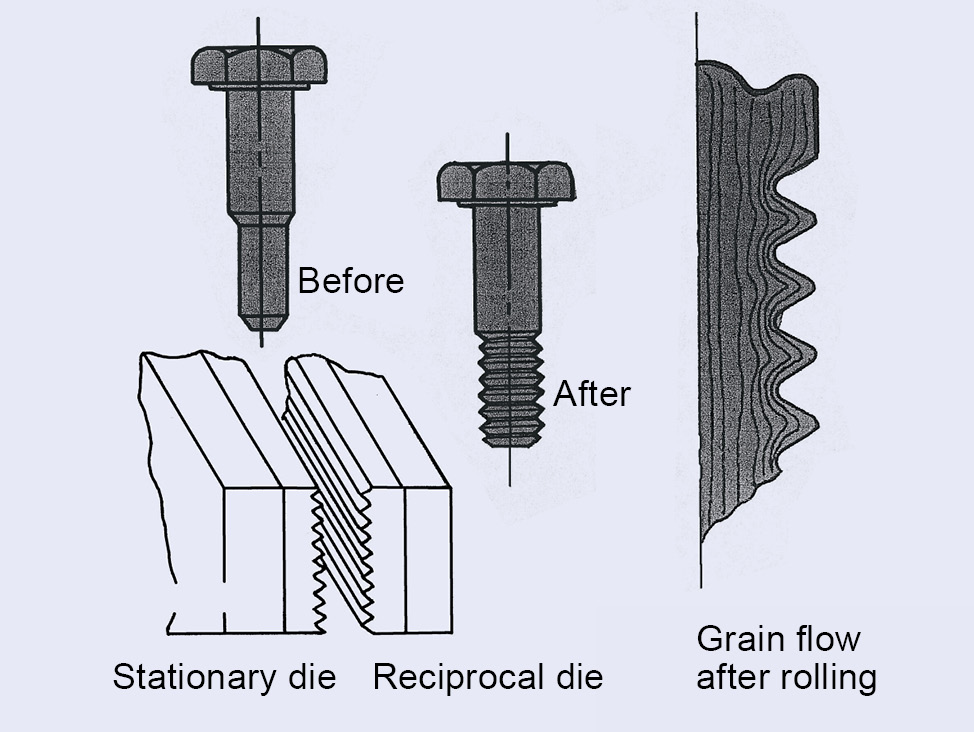

Figure 4: in the process of screw thread rolling, billet has accurate in two parallel groove rolling between flat die.Cold or hot working, rolling thread strong and smooth, do not waste material.